SPECIFICATION GENERATOR

Find out which low impact materials are right for your building project.

Our first UK manufactured product!

We scour the markets looking for new and innovative products and whilst we find some in the UK, quite often they lack the testing and technical documentation required for us to incorporate them in to our specifications.

Thankfully, that has now changed.

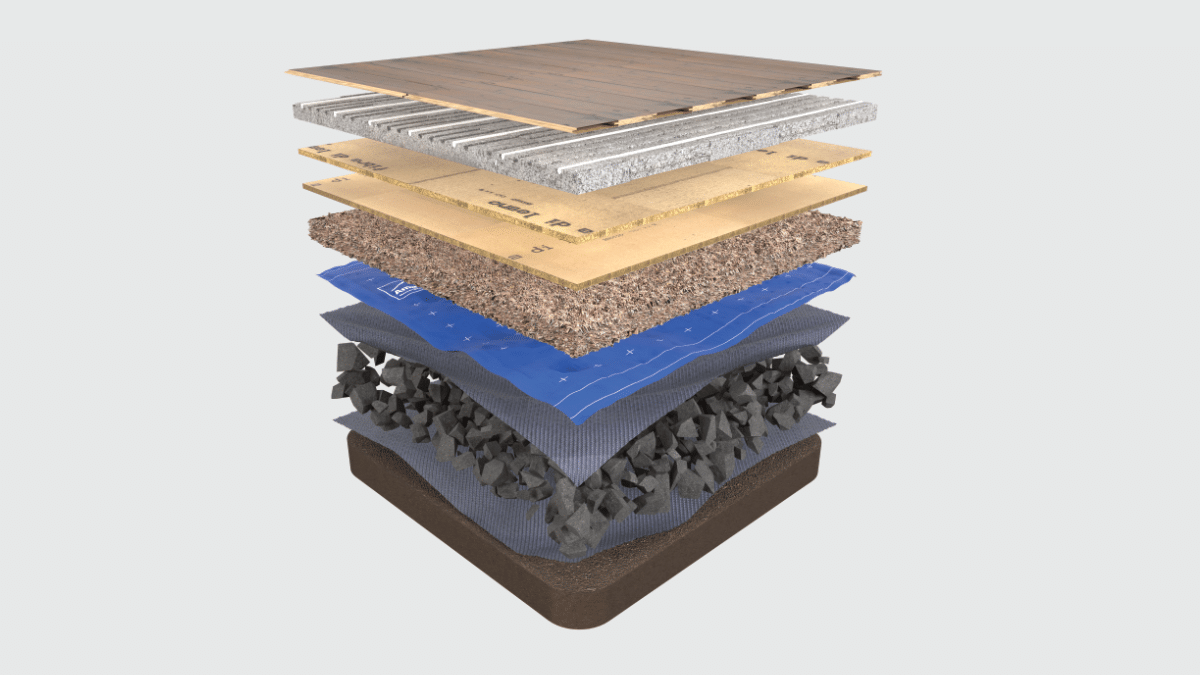

One of the specifications we have created for a fully re-useable solid floor, Lithoglas, uses a product called Foamglass or Foamed Glass. This products takes 100% recycled glass and converts it into a pumice-like aggregate that is strong enough to use under roads, bridges and floors but provides excellent insulation, is free draining and provides a capillary break.

Until now, we had been supplying foamglass manufactured in Germany and whilst it is a good product, we regularly got feedback that even after being compacted, the pieces of foamglass aggregate keep moving around and the surface was not very solid after compaction. Whilst we have always been confident in the product, it wasn’t very confidence inspiring for our customers.

The new product we’re supplying is called FG40, manufactured by Foamed-Glass UK in North Yorkshire. This foamglass knits together firmly and feels very solid when you walk over it, only reducing it’s volume by around 20% after compaction, compared to over 30% with the previous products used.

This solid surface has enabled us to change the position of the vapour control/damp/airtightness membrane within our Lithoglas specification to make it easier to seal around soil pipes and other penetrations and improved the build ability of the whole floor construction.

Over the foamglass and membrane we still use the Cemwood CW2000 levelling aggregate to create a dead level surface but the greater solidity of the FG40 product means it is easier to be more accurate with the foamglass levels and reduce the amount of Cemwood required.

In addition to this we have removed the T&G wood fibre boards initially designed in over the Cemwood, in favour of two layers of 20mm square edged boards. This makes it much easier and quicker to lay the boards and improves the thermal performance of the floor.

The Lithotherm underfloor heating tiles are then laid over the top of the wood fibre boards and finally finished with either timber flooring or tiles.

To find out more about our Lithoglas solid floor insulation specifications, click here or the FG40 foamglass product, click here.