SPECIFICATION GENERATOR

Find out which low impact materials are right for your building project.

What is a Vapour Control Layer (VCL)?

Find out more about how we approach this building scenario.

Here we look at what a Vapour Control Layer is, how a Vapour Control Layer (VCL) works, the types of VCLs available and if vapour check plasterboard is a viable alternative.

What is a vapour control layer?

In simple terms, this is a layer on the inner face of the building which is used to reduce moisture flow into and through the walls, roof or floor. This is to prevent damaging levels of condensation occurring in the fabric of the building which in turn would cause decay in timber, corrosion in metals or frost damage in masonry.

Vapour control layers differ from vapour barriers in that they are designed to slow the flow of moisture and not block it completely, the reason for which we explain below. Vapour control layers are also airtight and generally used as an airtight layer to make buildings airtight.

Understanding your walls, temperatures and condensation

With a plethora of membranes on the market, each designed to do slightly different jobs and behave in a subtly different way it is easy to be confused about which membranes are required to create a dry and airtight building structure.

Firstly, starting with the basics, when you insulate walls you create a temperature gradient across them with the warmest being on the inside and coolest on the outside during the winter months. You can imagine a graph of the temperature showing a fairly steady decrease in temperature as you move from the inside to the outside surface of the wall.

Secondly, when you take warm, moist air and cool it you find that the moisture in it condenses, usually on to the surfaces of the container it is within. If you pass this same air through the walls of your building the same condensation process occurs but instead of being in a container, it accumulates inside the fabric of your walls, roof or floors or your insulation.

How does moisture affect buildings?

Different construction and insulation materials cope differently with this condensation. Some materials, such as masonry, can absorb and release it again once the weather warms without too much damage. However, when using vapour impervious insulations in timber frame construction, any condensation forming in the walls tends to be absorbed by the timber, a process that can cause rot. Additionally, during the winter months when this condensation tends to occur, driving rain may also enter the fabric of the building, further increasing moisture levels in walls. It is therefore very important to prevent this condensation process occurring in walls, for the longevity of the building.

During the summer months, the temperature gradient is reversed and the higher temperature is found on the outside of the wall and the lower temperature on the inside. This creates a situation where moisture is driven inwards and condensation can form close to the inner face of the wall instead.

Why you shouldn’t use a vapour barrier in your walls

In the UK until relatively recently an impervious full vapour barrier was used on the inner face of a timber frame and was thought to prevent condensation formation by simply blocking the flow of moisture-laden air through the wall. However, it has since been found that not only are vapour barriers regularly full of holes which let moisture through during the winter months, they also cause the accumulation of moisture inside the wall during the summer months by preventing moisture escaping towards the interior of the building.

The high humidity levels and warm temperatures found in these walls combined to form perfect conditions for mould and rot to thrive. This was problematic to both the timber structure, as it rots, but also to the inhabitants of the building as mould spores are well known to cause respiratory problems and ill health.

Vapour barriers can still be useful though. One of the few places above ground level where a complete vapour barrier should be used is in flat roofing when using foil-faced PIR insulation. In this case, you need to lay a full vapour barrier on top of your flat roof deck before you lay the insulation and your flat roof covering. Swimming pools are another area where a full vapour barrier, such as the Ampatex Sisalex 518, should also be used because of the persistently high levels of moisture within the building.

Using a vapour control layer to control condensation

The answer to keeping timber-framed walls and roofs dry is to use a layer to restrict the flow of moisture but not to try and stop it. This is known as a vapour control layer (VCL) or a vapour retarder. A VCL is always used as close to the inner face of a wall as possible and reduces the amount of moisture passing through the layer to low levels, ensuring only insignificant amounts of condensation occur within the structure. Additionally, VCLs will allow moisture that is driven towards the interior in the summer months to slowly pass back inside the building. This prevents the conditions for mould forming and ensures the longevity of the structure.

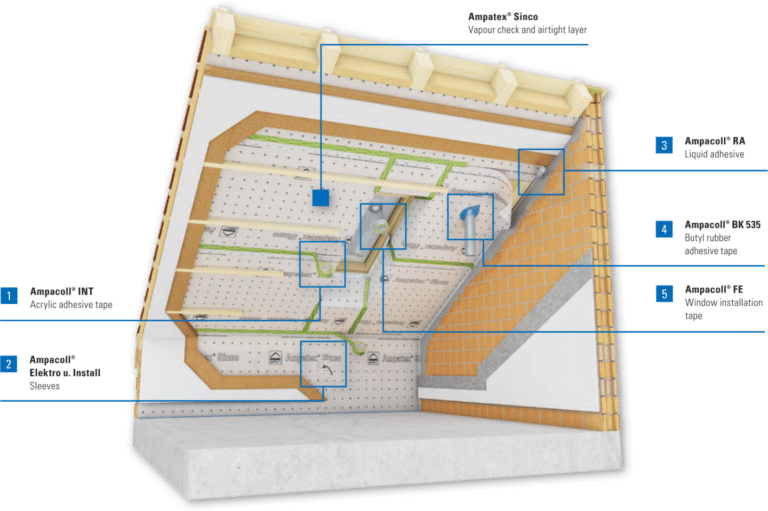

Vapour control can be performed very accurately by the many membranes available but it can also be performed at a basic level by OSB, whose vapour resistance (or vapour permeability) is similar to that of some membranes. The benefit of using OSB as a VCL is that it is far more robust than a 0.2mm membrane and does not require the installation of another layer into your timber frame structure if used internally. However, you will need to test the airtightness of the OSB before using it as there is some variation in air permeability. For guaranteed results either use the Smartply VapAirtight OSB or an airtight VCL membrane, such as the Ampatex Sinco membrane.

The latest type of VCL membrane is the ‘intelligent’ membrane, such as the Ampatex Variano membrane or Proclima’s Intello membranes. These are very useful products that remain very vapour tight (low vapour permeability) during the winter months when it is important to try and prevent moisture from entering your structure from the interior. As temperature and humidity in the walls rises the pores in the membrane open and allow moisture to migrate towards the interior of the building. This gives the best of both worlds and ensures your structures remain as dry as it is possible to be.

Using a vapour-check or foil backed plasterboard as a VCL

Vapour control layers are always required whenever you insulate, irrespective of the insulation used. They should be used to form a continuous airtight layer and so all the joints and any penetrations must always be sealed with the appropriate airtightness tapes. Without good levels of airtightness, the VCL does not work and moisture levels cannot be controlled inside the walls, roof or floors of the building. Products such as vapour-check, foil backed or insulated plasterboard tend to act as a vapour barrier but with none of the joints or penetrations sealed. These products may cause moisture to accumulate and should not be used instead of a VCL or where a VCL is used.

If you have any questions about how, when and where to use a vapour control layer please do contact us at chris@backtoearth.co.uk or alternatively give us a call on 01392 861763.

If you’re looking for a Vapour Control Layer, check out our Ampack and UdiSTEAM membranes: